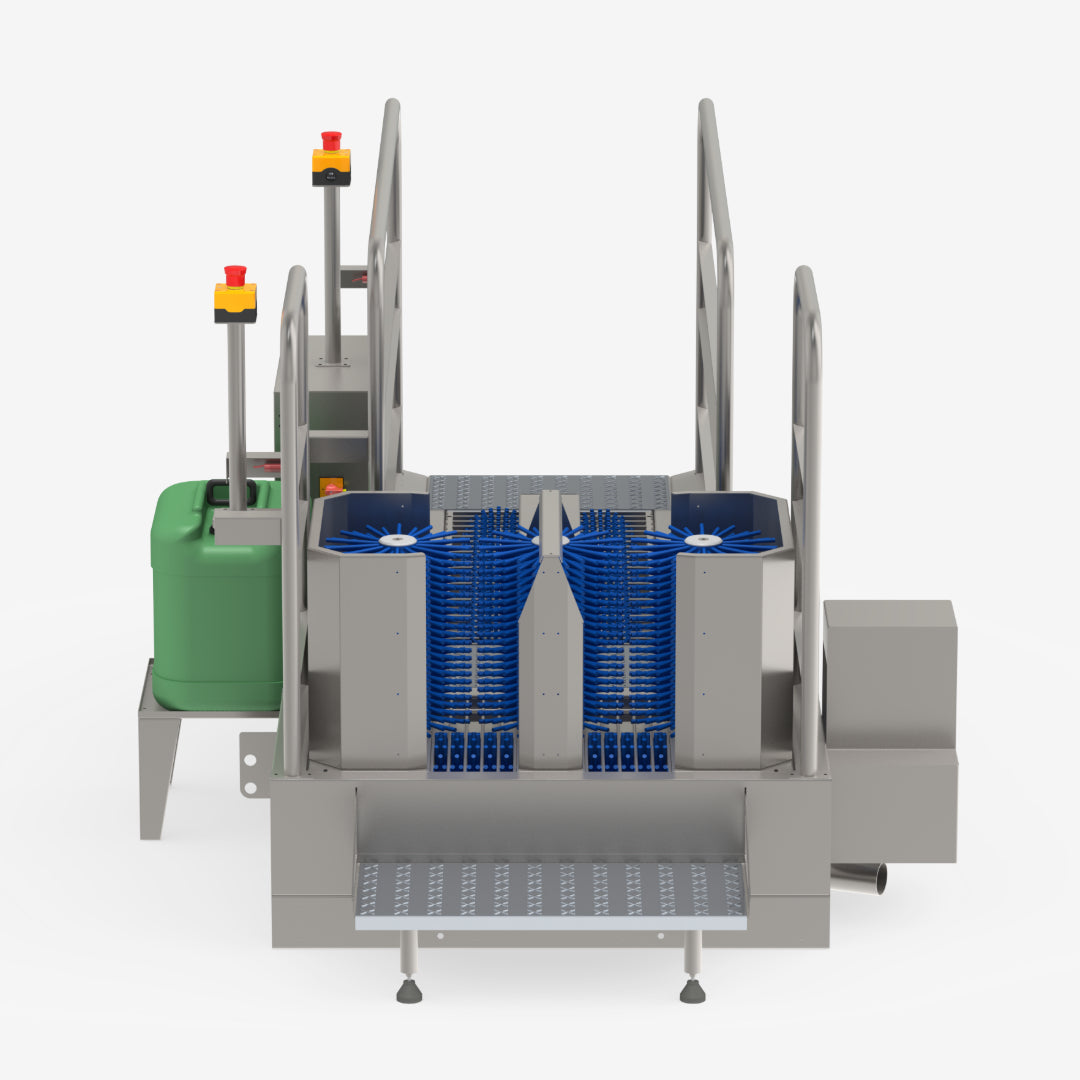

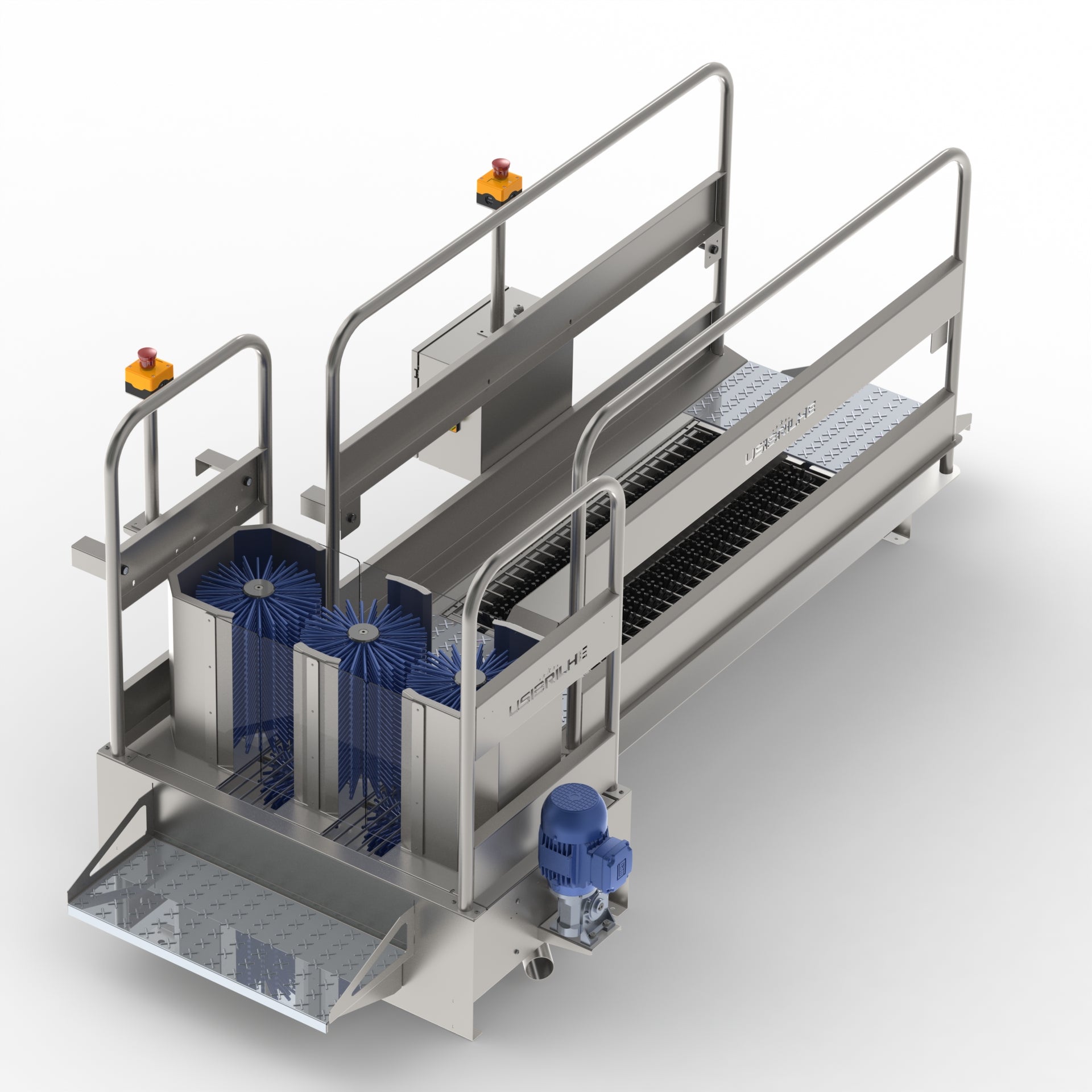

Boot Washer SC-09 | Complete High-Flow Walkway

⠀

Click the button above and request your proposal hassle-free. The process is simple, takes less than 3 minutes and you will receive a response within 1 business day. Speed up your purchases with fast, professional service focused on your company’s needs.

⠀

⠀

Choose options

⠀

Click the button above and request your proposal hassle-free. The process is simple, takes less than 3 minutes and you will receive a response within 1 business day. Speed up your purchases with fast, professional service focused on your company’s needs.

⠀

⠀

⠀

Click the button above and request your proposal hassle-free. The process is simple, takes less than 3 minutes and you will receive a response within 1 business day. Speed up your purchases with fast, professional service focused on your company’s needs.

⠀

⠀

Companies with a large number of employees, such as slaughterhouses, dairies, and processing industries, will find in the SC-09 the perfect solution to handle the high demand for sanitization.

Overview

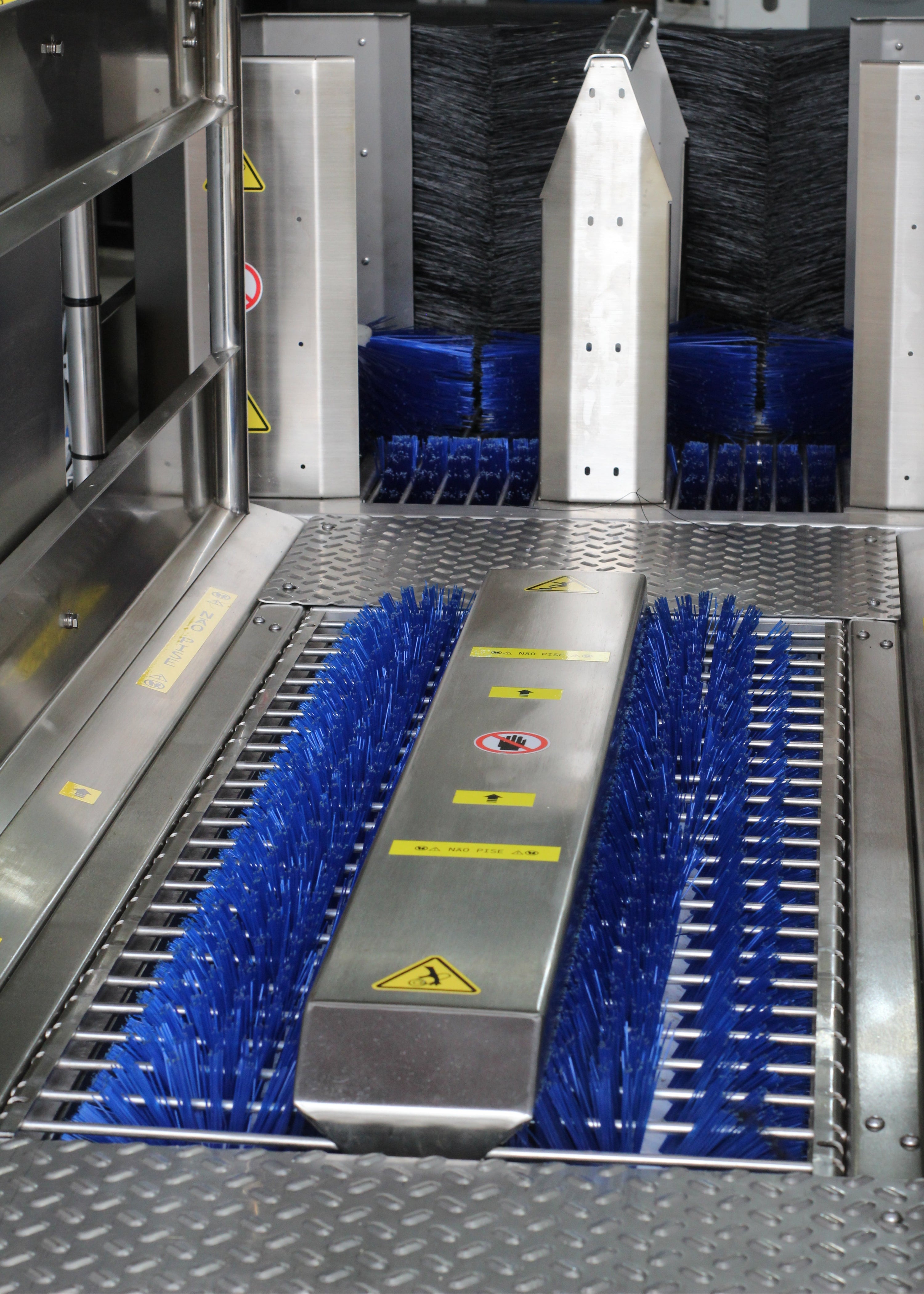

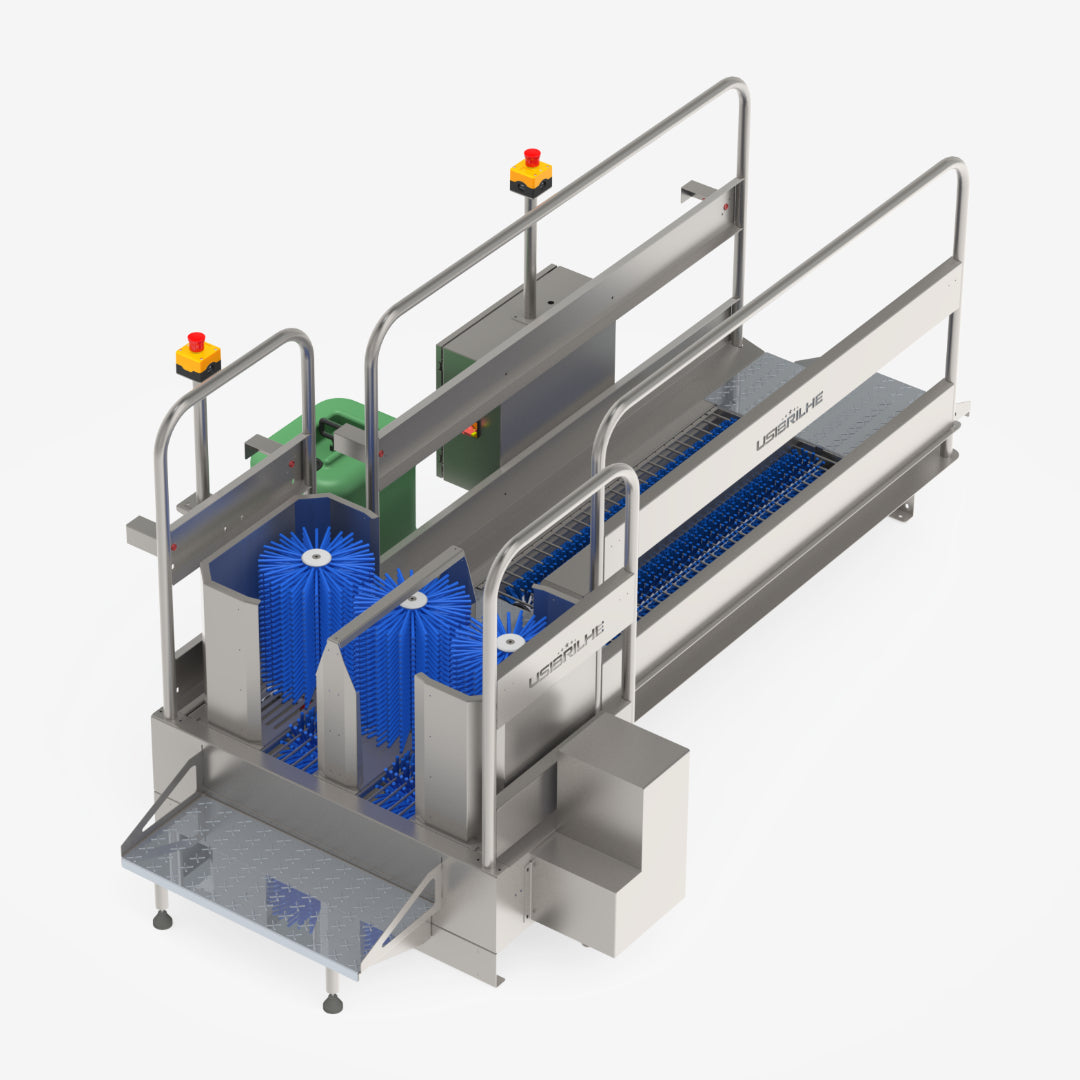

The Boot Washer SC-09 combines technologies from models SC-05 (vertical brushes) and SC-06 (horizontal and side brushes) in a single high-flow module. It removes mud, oil, and chemical residues from soles and sides in ≈ 6 s per employee. Built in 304 stainless, it withstands harsh environments in slaughterhouses, dairies, petrochemicals, mining, and other plants with high contamination levels.

How It Works

-

Presence sensors activate the cycle at the first step.

-

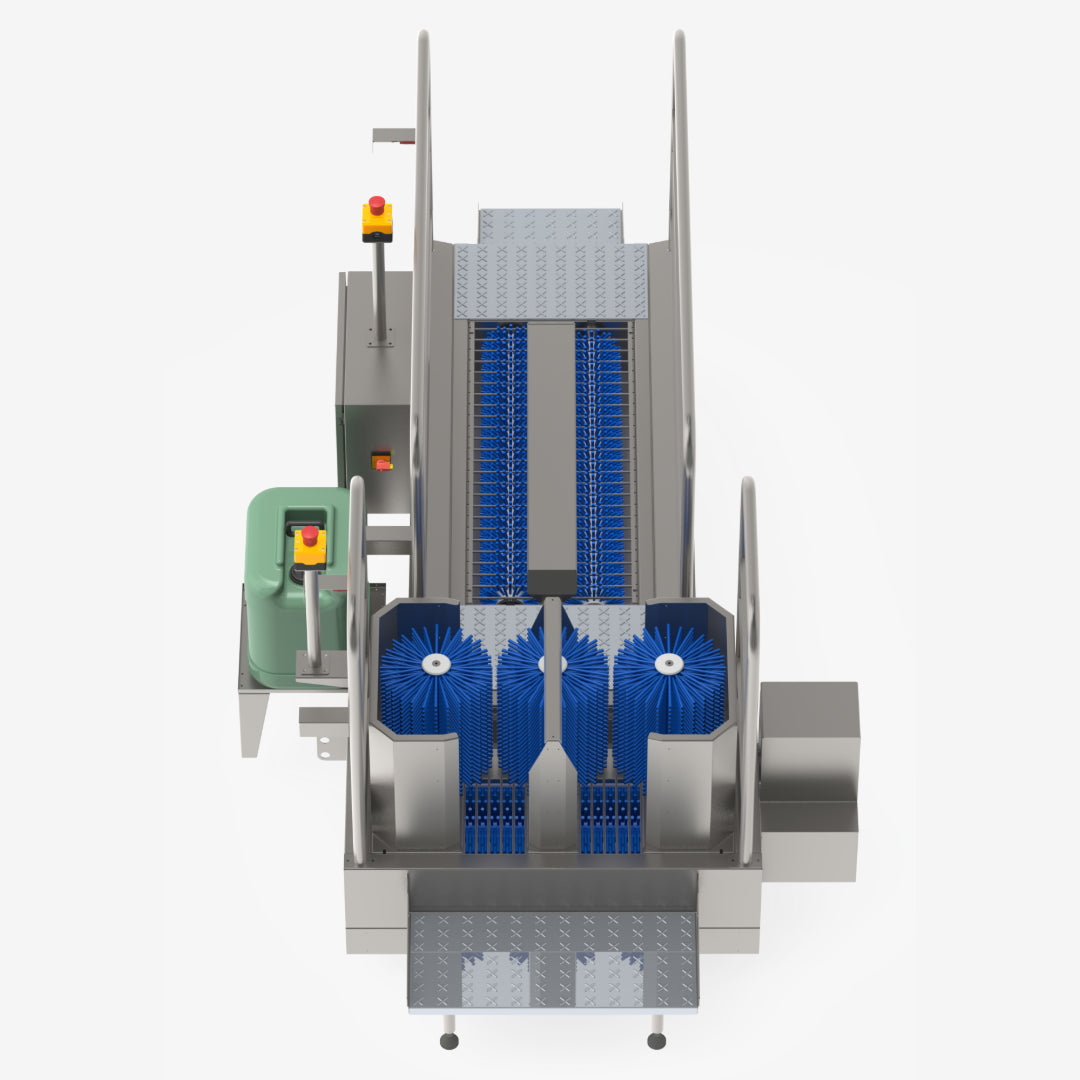

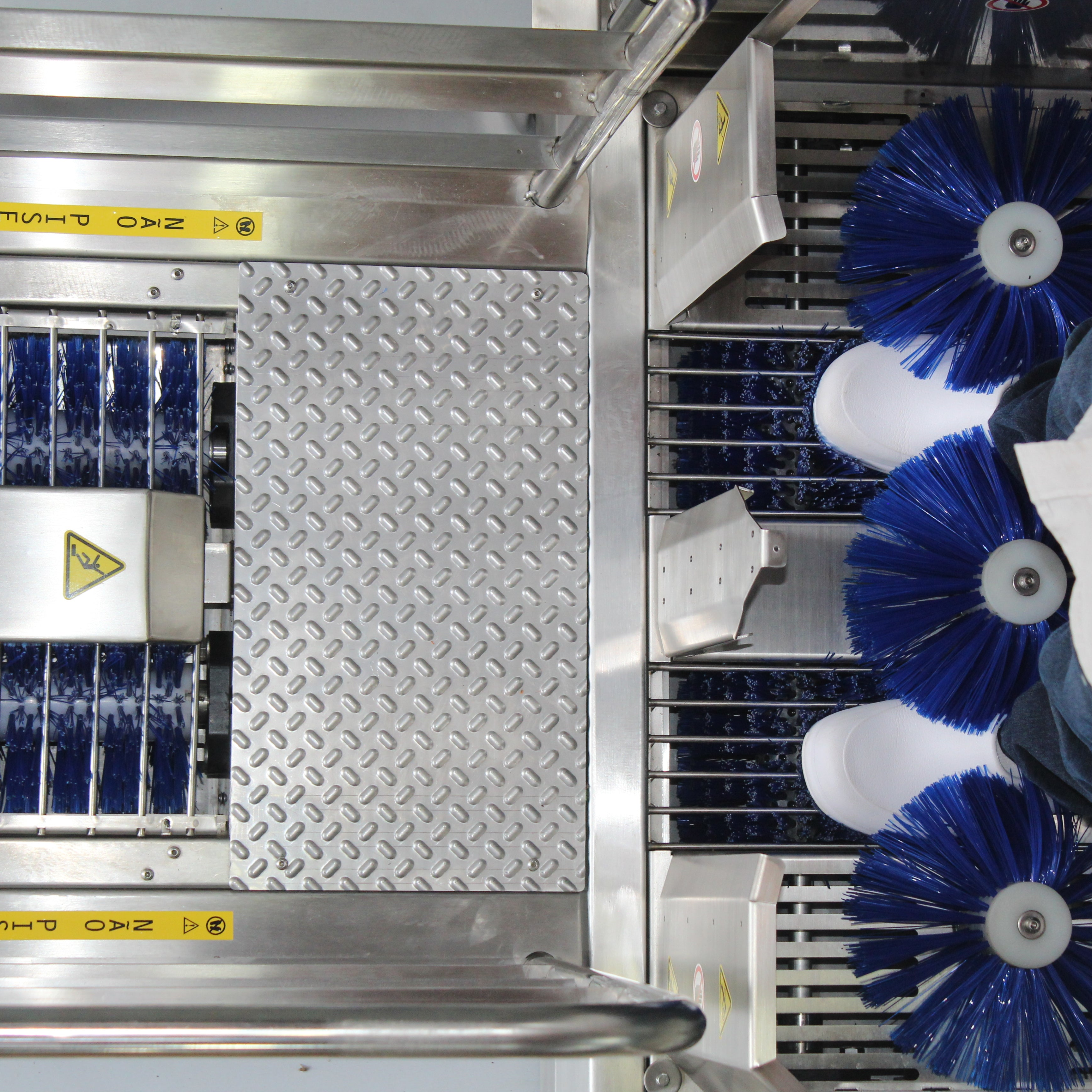

Step 1 – Integrated SC-05: vertical rotating brushes clean the sole from all angles.

-

Step 2 – Integrated SC-06: horizontal + side brushes remove remaining residues, while nozzles spray sanitizer directly onto the brushes.

-

The automatic cycle ends in ~6 s, allowing continuous flow without lines.

Practical examples

-

Slaughterhouse: prevents biological residues from reaching cutting lines.

-

Petrochemical: removes persistent oil before clean areas, reducing accident risks.

Usage Indications

-

Slaughterhouses and Dairies – critical hygiene for food safety.

-

Oil, Gas, and Petrochemical – removal of grease, solvents, and chemicals.

-

Mining and Heavy Industry – mud, mineral dust, and abrasive particles.

-

Chemical & Beverages – compliance with international sanitary standards.

Market Differentials

-

360° Cleaning: vertical, horizontal, and side brushes treat all shoe surfaces.

-

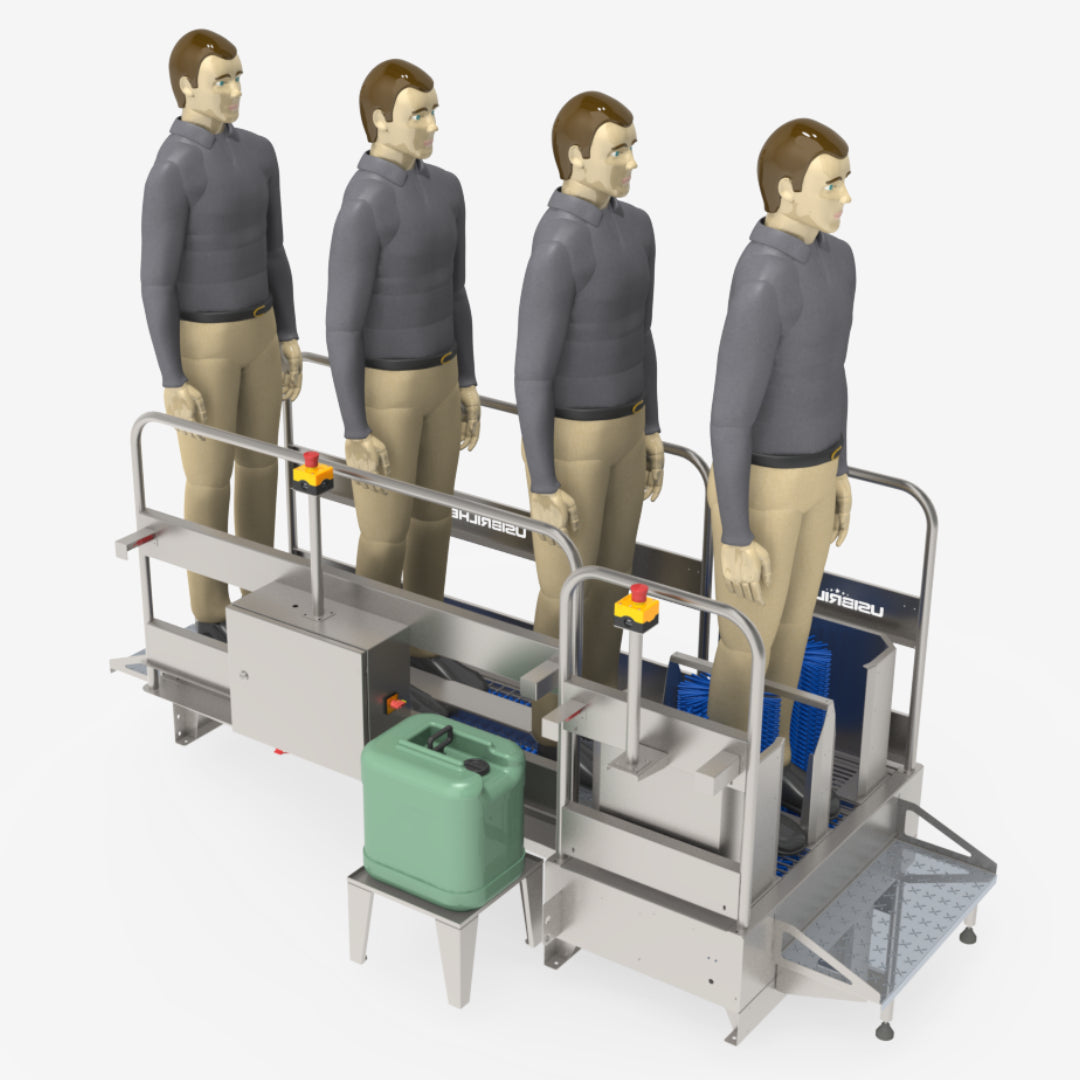

High flow: processes up to four employees simultaneously, ideal for large shifts.

-

Full customization:

• Adjustment of brush rotation and height.

• Control of sanitizer pressure and volume.

• Additional modules for walkway extension.

• Waste drawers front or side according to layout. -

Smart automation: sensors activate only when necessary, saving energy.

Maintenance and Durability

-

Structure in 304 stainless and IP66 electrical components (dust + water jets).

-

Quick-change brushes (no tools) with 3–4 years lifespan.

-

Hygienic design that facilitates cleaning and minimizes accumulation points.

Operational Efficiency & Savings

-

Precise sanitizer dosing prevents waste.

-

Automatic shutdown reduces power consumption.

-

Integrates with access control systems and biometric readers, maintaining employee flow without interruptions.

Safety and Compliance

-

Emergency stops accessible along the walkway.

-

Covers prevent contact with moving parts.

-

Design in compliance with NR-12 and Good Manufacturing Practices.

Conclusion

For plants that demand complete, fast, and continuous sanitization, the SC-09 delivers deep cleaning, robustness, and versatility without compromising production pace. If the goal is to maintain high sanitary standards while handling heavy dirt and high employee flow, the SC-09 is the ultimate choice. Request a quote and discover how to integrate it into your process.

ELECTRICAL SUPPLY

- Voltage: 220V

- Frequency: 50/60Hz

- Power: 3000W

- Plug: 3 pins (2P+T) NBR 14136

MOTORS AND CONTROL

- Motors: 3 three-phase gear motors

- Motor Power: 0.75HP / 0.55KW each

- Number of Poles: 4 poles

- Speed Control: Speed variation via frequency inverter (WEG brand)

SANITIZATION SYSTEM

- Method: Sole and side brushing with water and sanitizer spraying

- Suction and Spraying System: Yes

- Water Consumption: Adjustable via ½-inch hose (½” fitting)

- Water Drainage: 2 ½-inch pipe (non-reusable water)

- Brush Type: Replaceable brushes with customizable height according to shoe/boot

- Average Sanitization Time per Person: 6 seconds (varies depending on dirt level)

- Contaminants Removed: Dust, sand, oil, grease, lubricants

CONTROL PANELS

- Electrical Panel: Present in all versions

- Hydraulic Panel: Not applicable (water system with hose connection)

SENSORS AND AUTOMATION

- Activation: Automatic via presence sensor (entry and exit)

- Control: Via digital signal

DIMENSIONS AND WEIGHT

- Equipment Weight: 380kg

- Dimensions: Height: 118 cm | Width: 140 cm | Length: 278 cm

- Capacity: 4 people simultaneously

STRUCTURE AND CONSTRUCTION

- Material: AISI 304 Stainless Steel

- Finish: Welded seams for easy cleaning and corrosion resistance

BRUSHES

- Bristle Material: Polyamide

- Replacement System: Quick replacement without tools

CERTIFICATIONS AND STANDARDS

- Certification: Regulatory Standard NR12 (compliance with safety standards)

WARRANTY

- Warranty Period: 12 months (National product)

Download Center

Here you can quickly access and download essential documents for your equipment. Choose the desired content below:

Didn’t find what you needed? If you need other technical documents, contact our engineering team via WhatsApp.

Trusted by market leaders around the world

ensure total boot cleaning in just a few seconds.

Maximum performance

With brushes that rotate horizontally and vertically, the SC-09 ensures complete sole cleaning in all directions. The brushes perform full sanitization by cleaning the entire length of the footwear, ensuring that no area is left untreated.

By combining the SC-05 and SC-06 models, the SC-09 offers the most complete cleaning possible, removing dirt such as mud, oil, paste and heavy residues that require robust and efficient solutions.

Perfect for slaughterhouses, dairies, and heavy industries

Designed for High Workflows

Companies with a large number of employees, such as slaughterhouses, dairies, and processing industries, will find in the SC-09 the perfect solution to handle the high demand for sanitization. The equipment maintains efficiency in continuous operations, ensuring each employee undergoes full sanitization without losing time.

Leader in Brazil in industrial sanitization

Usibrilhe’s Most Advanced Technology

The SC-09 represents the integration of Usibrilhe’s most innovative solutions. We are leaders in the Brazilian footwear sanitization market, and this equipment is the peak of our technology, designed to meet the most demanding industries, from slaughterhouses and dairies to mining and large factories.

standards met

We help your company comply with HACCP, preventing contamination and standardizing sanitization.

The automation and sanitary control of our products contribute to the safety required by FSSC 22000.

Our solutions help ensure compliance with ISO/22000, guaranteeing hygiene and food safety.

Adaptable for any type of footwear and situation

Tailored Customization

Different industries have specific needs, and the SC-09 is designed to meet all of them. With height adjustment options and sanitizer spray intensity, the equipment adapts to any type of footwear, from industrial boots to smaller shoes. This means it can be configured for diverse environments, such as food, pharmaceutical, chemical industries, and much more.

nosso produto, testado na

practice

Ready to integrate the SC-09 into your company?

Request Your Quote Now

Click the "Request Quote" button and tell us your specific needs. Our team will adjust the SC-09 to offer a personalized solution that meets your operation’s requirements with maximum efficiency and cost-benefit.

a little more about the

equipment benefits

⠀

Time Savings

The SC-09 allows employees to quickly go through the sanitization process without interruptions, ensuring workflow continues without delays.

Safety for All

With emergency systems and automatic stops, the SC-09 ensures total safety during use, preventing accidents and ensuring a safer workplace.

Zero Contamination

By ensuring complete cleaning of footwear in all directions, the SC-09 reduces the risk of cross-contamination, keeping production environments safe and impurity-free.

Perguntas

Here we have gathered the main questions about the product and their answers.

Usage and Applications

The SC-09 is recommended for industries with high employee traffic and strict sanitization requirements, such as slaughterhouses, dairies, food industries, pharmaceuticals, chemicals, mining, and other sectors requiring strict sanitary control.

The SC-09 offers complete footwear sanitization, cleaning the sole from all angles and the sides. This is possible thanks to the combination of SC-05 and SC-06 model technologies, which use vertical and horizontal brushes, as well as side brushes.

The SC-09 integrates the SC-05 and SC-06 equipment in series, positioned one in front of the other, forming an integrated unit. This combination allows for more complete sanitization, combining the advantages of both models into one piece of equipment.

Yes, the SC-09 was designed to handle large user volumes, maintaining efficiency and sanitization quality. It is ideal for companies that need to process many employees without compromising workflow.

Customization and Configuration

Yes, it inherits all customization capabilities from the SC-05 and SC-06 models. It is possible to adjust brush rotation, brush height, and sanitizer spray intensity, adapting to different footwear types and dirt levels.

The SC-06 uses adjustable brushes to scrub boot soles and sides, while nozzles spray sanitizer directly onto the brushes for effective cleaning.

It is compatible with all types of industrial footwear, from low shoes to heavy boots. The adjustable brushes ensure effective cleaning of different sizes and shapes of footwear.

Operation and Use

Users simply walk through it, passing first through the SC-05 and then through the SC-06. The transition is smooth, and both pieces of equipment operate automatically, ensuring complete sanitization without the need for pauses or additional actions.

Yes, it can be configured for sanitization in both directions, depending on the specific needs of the workplace.

Maintenance and Durability

The SC-09 brushes have an estimated lifespan of 3 to 4 years, depending on use and operating conditions.

Maintenance is simplified thanks to its design. The brushes can be easily replaced without special tools. Periodic inspections are recommended to ensure optimal performance and equipment longevity.