Boot Washer SC-06 | Total Sanitization

⠀

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

Choose options

⠀

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

⠀

⠀

Click the button above and request your proposal without hassle. The process is simple, takes less than 3 minutes and you receive a reply within 1 business day. Speed up your purchases with fast, professional service focused on what your company needs.

⠀

⠀

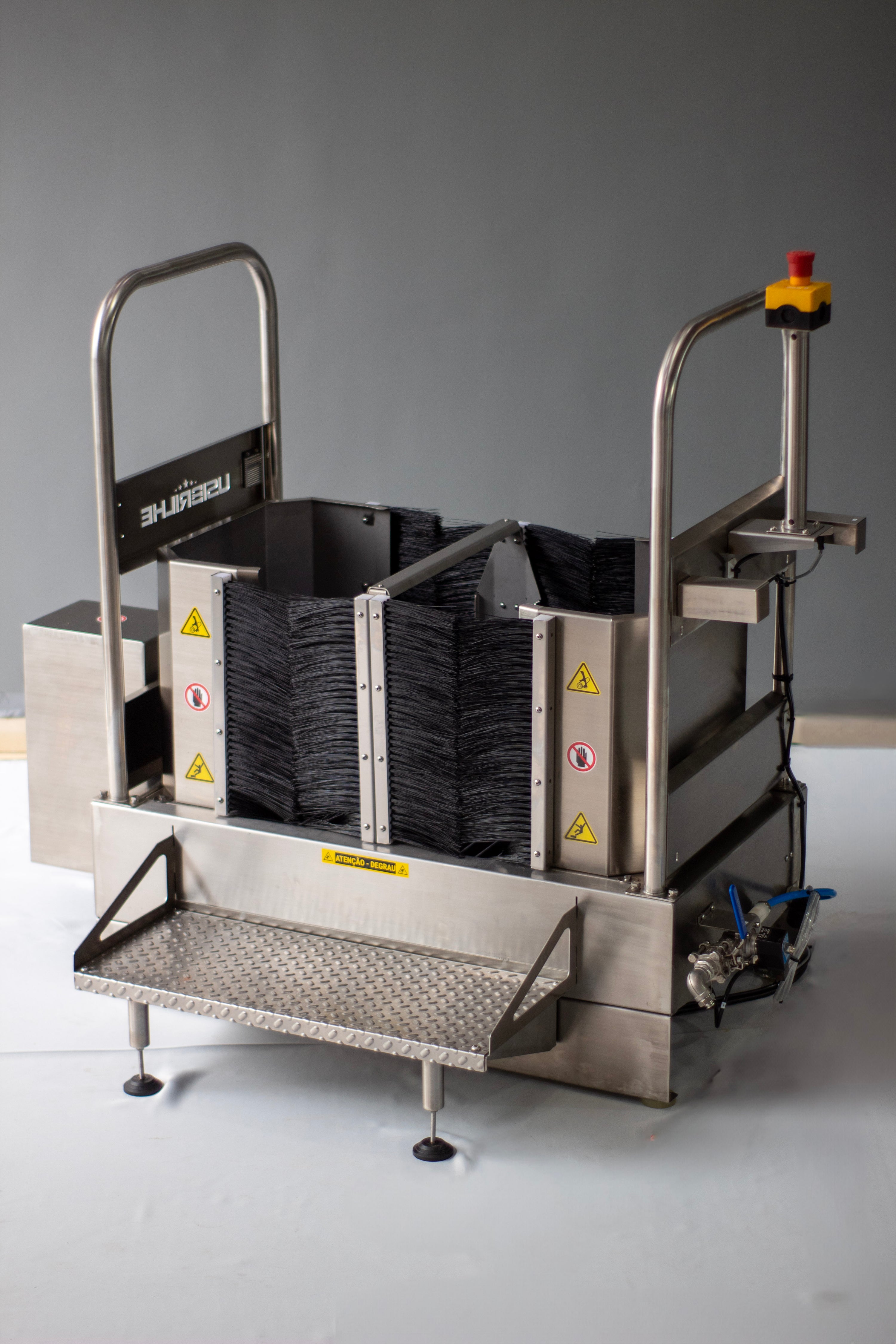

The SC-06 is an automatic boot washer designed to remove dirt from the soles and sides of industrial boots. With adjustable brushes and an integrated sanitization system, it removes contaminants such as oil, mud, and chemical residues.

Visão Geral

A Lava Botas SC-06 é uma passarela automática construída em inox 304, projetada para remover lama, óleo e resíduos químicos de sola, laterais e cano em segundos. Indicada para frigoríficos, laticínios, petroquímicas e qualquer planta com alto rigor sanitário.

Como Funciona

-

Sensores de presença ativam o equipamento ao primeiro passo.

-

Escovas ajustáveis limpam todos os lados da bota.

-

Bicos de pulverização aplicam sanitizante nas escovas.

-

O ciclo termina e o sistema desliga, economizando energia.

Indicações de Uso

-

Alimentos – frigoríficos, laticínios e abatedouros.

-

Óleo e Gás / Petroquímico – remoção de graxa, solventes e hidrocarbonetos.

-

Químico & Farmacêutico – áreas que exigem controle microbiológico.

-

Indústrias pesadas – evita transferência de contaminantes entre setores.

Diferenciais

-

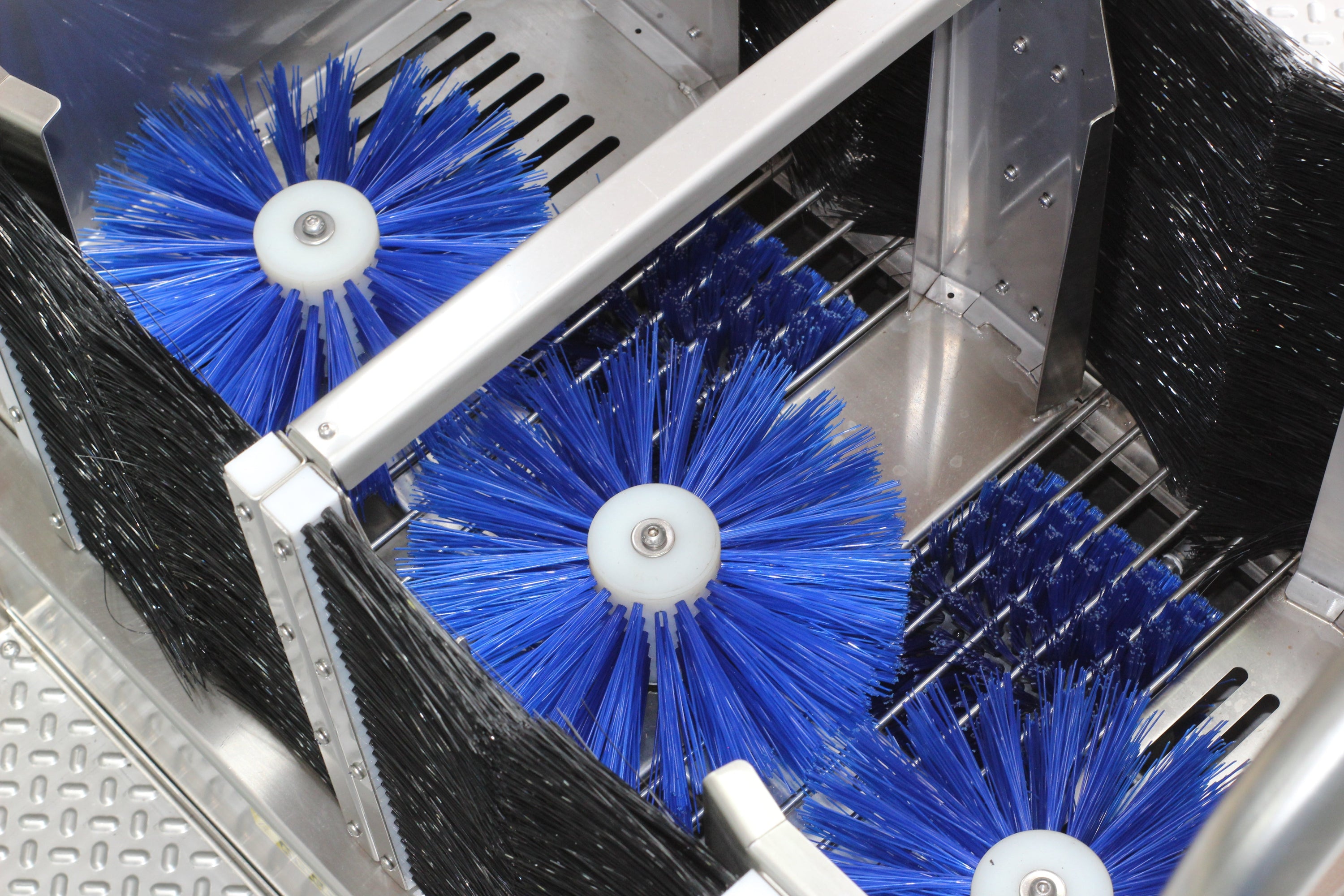

Cobertura total – sola, laterais e cano em um único percurso.

-

Escovas ajustáveis – adapta-se a diferentes alturas de botas.

-

Automação completa – operação sem intervenção manual.

-

Pulverização integrada – higieniza e sanitiza de forma simultânea.

Manutenção e Durabilidade

-

Estrutura em inox 304 resistente à corrosão.

-

Escovas de troca rápida sem ferramentas.

-

Componentes elétricos IP66 protegem contra água e poeira.

-

Vida útil das escovas: 3–4 anos (uso normal).

Eficiência Operacional

-

Ciclo de limpeza em segundos; suporta alto fluxo de pessoas.

-

Sistema de sanitizante dosa apenas o necessário — sem desperdício.

-

Desligamento automático reduz consumo de energia.

Segurança e Conformidade

-

Paradas de emergência ao alcance do usuário.

-

Projeto em conformidade com NR-12 e Boas Práticas de Fabricação.

-

Carenagens evitam contato com partes móveis.

Conclusão

A SC-06 oferece higienização profunda, automática e econômica para botas industriais em ambientes críticos. Integre-a ao seu controle de acesso e garanta processos livres de contaminação com mínima intervenção humana.

Electrical Supply

- Voltage: 220V

- Frequency: 50/60Hz

- Power: 2000W

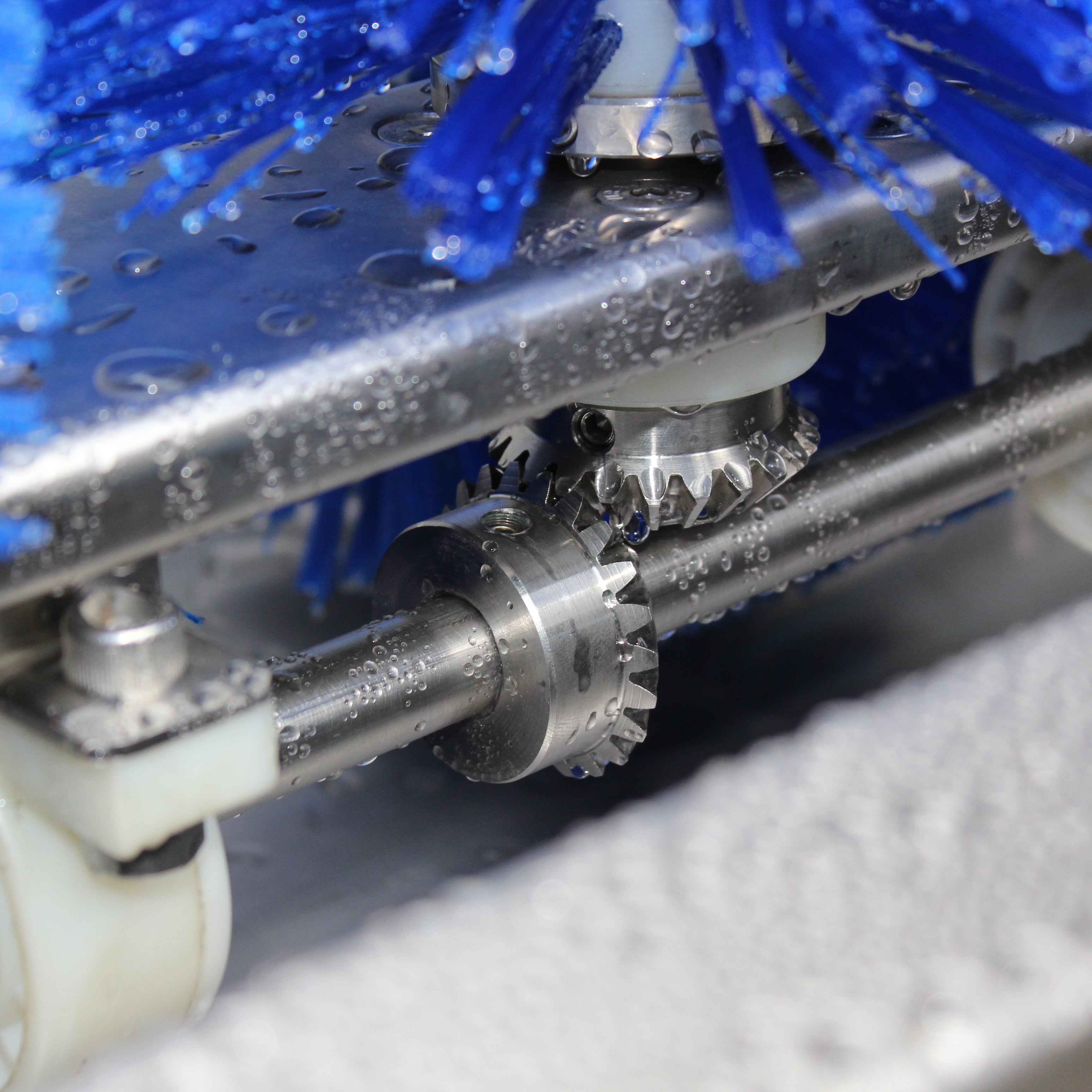

Motors and Control

- Motors: 1 three-phase gear motor

- Motor Power: 0.75HP / 0.55KW

- Number of Poles: 4 poles

- Speed Control: Speed variation via frequency inverter (WEG brand)

Sanitization System

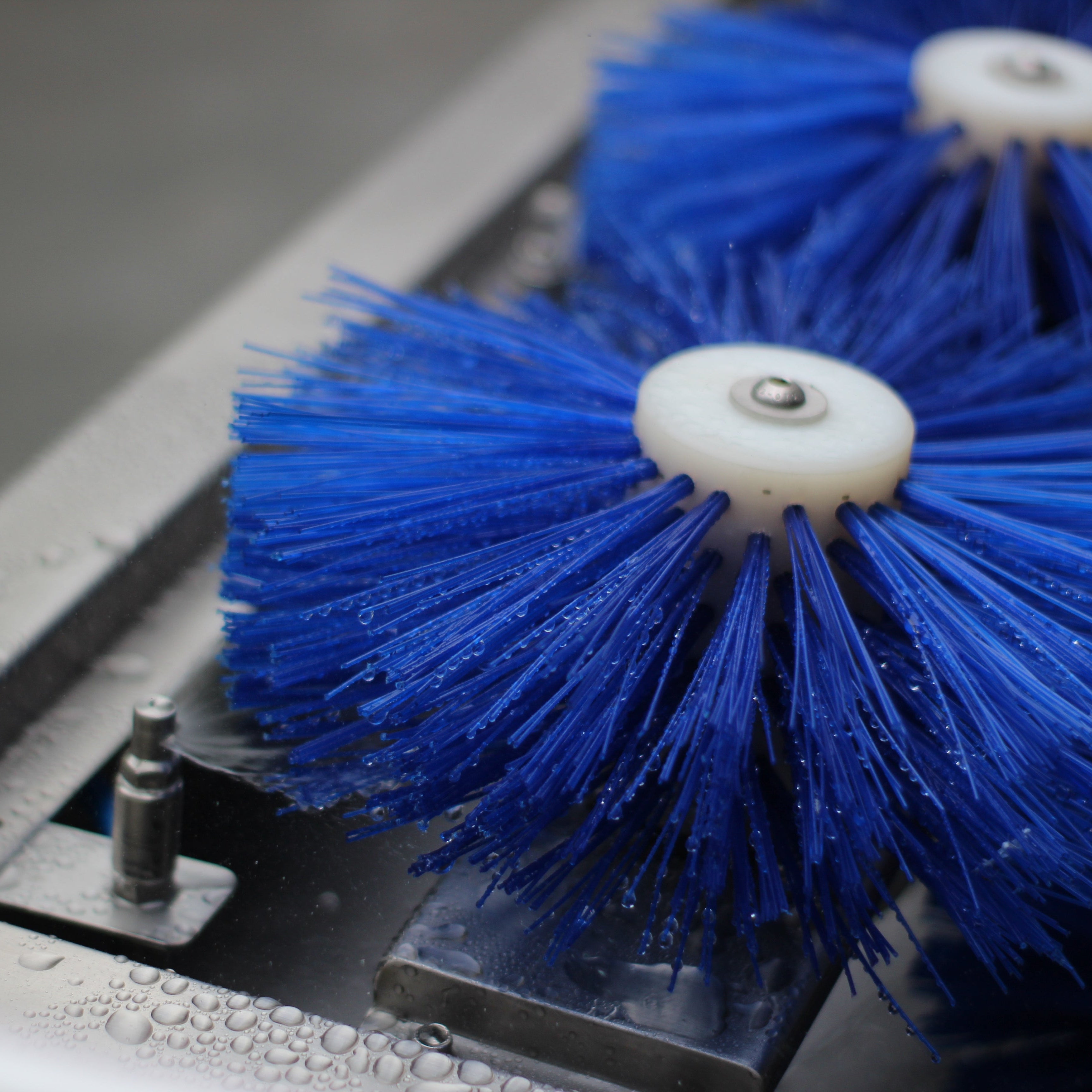

- Method: Sole and side brushing with water and sanitizer spraying

- Water Consumption: Adjustable via ½-inch hose

- Water Drainage: 2 ½-inch pipe (non-reusable water)

- Brush Type: Replaceable brushes with adjustable height

- Average Sanitization Time per Person: 5 seconds (varies depending on dirt level)

- Contaminants Removed: Dust, sand, oil, grease, lubricants

Control Panels

- Electrical Panel: Present in all versions

- Hydraulic Panel: Not applicable (water system with hose connection)

Sensors and Automation

- Activation: Automatic via presence sensor (entry and exit)

- Control: Via digital signal

Dimensions and Weight

- Equipment Weight: 90kg

- Capacity: 1 person at a time

Structure and Construction

- Material: AISI 304 Stainless Steel

- Finish: Welded seams for easy cleaning and corrosion resistance

Brushes

- Bristle Material: Polyamide

- Replacement System: Quick replacement without tools

Certifications and Standards

- Certification: Regulatory Standard NR12 (compliance with safety standards)

Warranty

- Warranty Period: 12 months (National product)

Trusted by market leaders around the world

ensure total boot cleaning in just a few seconds.

How Does the SC-06 Work?

Imagine your employees are about to enter a production area. When passing through the SC-06, they simply step on the platform and the equipment automatically starts the cleaning process. Strategically positioned adjustable brushes begin scrubbing the soles and sides of the boots, while nozzles spray sanitizer directly onto the moving brushes.

This system completely removes oil, mud, and any type of dirt that could compromise safety and hygiene inside your plant. The process is quick, lasting only a few seconds, and ensures your employees enter controlled environments with completely clean footwear.

robust construction

Built to Withstand the Most Demanding Environments

Made of AISI 304 stainless steel, the SC-06 withstands harsh environments and continuous use in sectors such as slaughterhouses and oil industries. Its long-lasting brushes are ideal for operations requiring consistent performance in extreme conditions. With a lifespan of up to 4 years, the SC-06 ensures high durability and low maintenance costs, making it the ideal choice for companies that value reliability and efficiency.

Compliant with the Strictest Standards

Keeping a contamination-free environment is crucial for industries operating under strict sanitary regulations. The SC-06 was designed to meet the highest industrial hygiene standards. In food industries, for example, where contamination control is vital, the SC-06 prevents external residues from contaminating products.

Likewise, in petrochemical plants, it protects risk areas by ensuring that boots do not carry oil residues into clean zones. This equipment is an additional layer of safety, helping your operation comply with regulations without compromising efficiency.

standards met

We help your company comply with HACCP, preventing contamination and standardizing sanitization.

The automation and sanitary control of our products contribute to the safety required by FSSC 22000.

Our solutions help ensure compliance with ISO/22000, guaranteeing hygiene and food safety.

Presence Sensor Activation

Speed Up the Process and Reduce Costs

The SC-06 is automatically activated by sensors. When detecting the user’s presence, the equipment starts the sanitization cycle without the need for manual operation. This optimizes the entry and exit flow of employees in critical areas, such as factories and processing plants. There is no waste of sanitizer or energy.

our product, tested in

practice

Ready to integrate the SC-06 into your company?

Request Your Quote

Click the "Request Quote" button and tell us your specific needs. Our team will adjust the SC-06 to offer a personalized solution that meets your operation’s requirements with maximum efficiency and cost-benefit.

a little more about the

equipment benefits

⠀

Low Operational Maintenance

With high-durability components and long-lasting brushes, the SC-06 requires little maintenance, reducing downtime.

Easy Installation

The SC-06 requires only one power point and sanitizer inlet, simplifying the installation process in any industrial environment.

Supply Savings

The spray system optimizes sanitizer use, ensuring effective sanitization with lower chemical consumption.

Questions

Here we have gathered the main questions about the product and their answers.

Usage and Applications

The SC-06 is ideal for food, petrochemical, slaughterhouse, dairy, and sectors requiring strict contamination and footwear hygiene control.

The SC-06 removes dirt such as mud, oil, grease, chemical residues, and other contaminants that may accumulate on boot soles and sides.

The SC-06 is suitable for all types of industrial boots, adjusting brushes to accommodate from shoes to large boots

Operation and Safety

The SC-06 is automatically activated by sensors that detect the user’s presence when stepping on the platform, starting the sanitization process without manual interaction.

The SC-06 uses adjustable brushes to scrub boot soles and sides, while nozzles spray sanitizer directly onto the brushes for effective cleaning.

Yes, the SC-06 has easily accessible emergency stops and all electrical components are IP66 certified, protecting against dust and water.

The sanitization process is quick, lasting only a few seconds, depending on the dirt level and configuration.

Warranty and Support

The SC-06 has a 12-month warranty.

Yes, we offer full support for maintenance of the SC-05. Contact our support team for more information.

Maintenance and Durability

The SC-06 brushes have an estimated lifespan of 3 to 4 years, depending on use and operating conditions.

No. The equipment was designed to require little maintenance, with brushes that are easy to remove and replace without tools.

Yes, the SC-06 is built in AISI 304 stainless steel, ensuring corrosion resistance and durability in harsh environments such as slaughterhouses and petrochemical plants.